About Bellows

Design

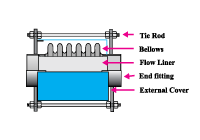

Expansion joints consist of a flexible bellows element with end fittings such as flanges to allow connection to the adjacent piping or equipment.

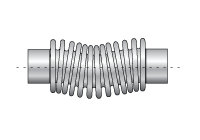

Bellows are manufactured from relatively thin-walled tubing to form a corrugated cylinder. The corrugations, commonly referred to as convolutions, add the structural reinforcement necessary for the thin-wall material to contain system pressure. The bellows designer selects the thickness and convolution geometry to produce a bellows design that approaches, and often exceeds the capacity of the adjoining pipe to contain system pressure at the specified design temperature.

Flexibility of the bellows is achieved through bending of the convolution sidewalls, as well as flexing within their crest and root radii. In most cases, multiple convolutions are required to provide sufficient flexibility to accommodate the expected expansion and contraction of the piping system.

Movement Capabilities

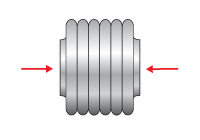

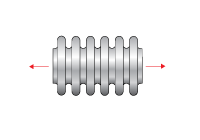

Axial Compression:

Reduction of the bellows length due to piping expansion.

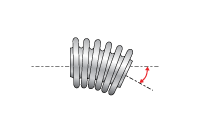

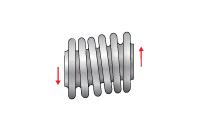

Angular Rotation:

Bending about the longitudinal center line of the expansion joint.

Torsion:

Twisting about the longitudinal axis of the expansion joint can reduce bellows life or cause expansion joint failure and should be avoided. Expansion joints should not be located at any point in a piping system that would impose torque to the expansion joint as a result of thermal change or settlement.

Axial Extension:

Increase of the bellows length due to pipe contraction.

Lateral Offset:

Transverse motion which is perpendicular to the plane of the pipe with the expansion joint ends remaining parallel.

Cycle Life

In most applications, design movements cause the individual convolutions to deflect beyond their elastic limits, producing fatigue due to plastic deformation, or yielding. One movement cycle occurs each time the expansion joint deflects from the installed length, to the operating temperature length, and then back again to the original installation length.

In the majority of applications, total shutdowns are infrequent, therefore a bellows with a predicted cycle life of one or two thousand cycles is usually sufficient to provide reliable fatigue life for decades of normal service. High cycle life designs may be desirable for service applications that include frequent start up/shut down cycles. The bellows designer considers such design variables as material type, wall thickness, the number of convolutions and their geometry to produce a reliable design for the intended service with a suitable cycle life expectancy.

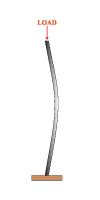

Squirm

An internally pressurized bellows behaves in a manner similar to that of a slender column under compressive load. At some critical end load, the column will buckle, and in a similar manner, at a sufficient pressure, an internally pressurized bellows that is installed between fixed points will also buckle, or squirm.

Bellows squirm is characterized by a gross lateral shift of the convolutions off of the longitudinal centerline. Bellows squirm can reduce cycle life, or in extreme cases, produce a catastrophic failure.

Bellows squirm is characterized by a gross lateral shift of the convolutions off of the longitudinal centerline. Bellows squirm can reduce cycle life, or in extreme cases, produce a catastrophic failure.

To avoid squirm, the bellows designer must limit movement capacity and flexibility to a level that insures that the bellows retains a conservative margin of column stability beyond the required design pressure.

End Fittings

Expansion joints will include appropriate end fittings such as flanges or butt-weld ends that should match the dimensional requirements and materials of the adjoining pipe, or equipment. Small diameter compensators are available with threaded male ends, butt weld ends or copper sweat ends. Threaded flanges may be added to the threaded end compensators if a flanged connection is preferred.

Accessories

Flow liners are installed in the inlet bore of the expansion joint to protect the bellows from erosion damage due to an abrasive media or resonant vibration due to turbulent flow or velocities which exceed:

For air, steam, and other gases

- Up to 6” dia.- 4 ft./sec./inch of diameter

- Above 6” dia. -25 ft/sec

For water and other liquids

- Up to 6” dia. – 2 ft./sec./inch of diameter

- Above 6” dia. -10 ft./sec.

Expansion joints that are installed within ten pipe diameters downstream of elbows, tees, valves or cyclonic devices should be considered to be subject to flow turbulence. The actual flow velocity should be multiplied by 4 to determine if a liner is required per the above guidelines. Actual or factored flow velocities should always be included with design data, particularly flow that exceeds 100 ft./sec. which require heavy gauge liners.

External covers are mounted at one end of the expansion joint, providing a protective shield that spans the length of the bellows. Covers prevent direct contact with the bellows, offering personnel protection, as well as protection to the bellows from physical damage such as falling objects, weld splatter or arc strikes. Covers also provide a suitable base for

external insulation to be added over an expansion joint. Some insulating materials, if wet, can leach chlorides or other substances that could damage a bellows.

Tie rods eliminate pressure thrust and the need for main anchors required in an unrestrained piping system. Axial movement is prevented with the use of tie rods. Designs that have only two tie rods have the additional ability to accommodate angular rotation. Limit rods are similar, however they accommodate a specified axial capability.